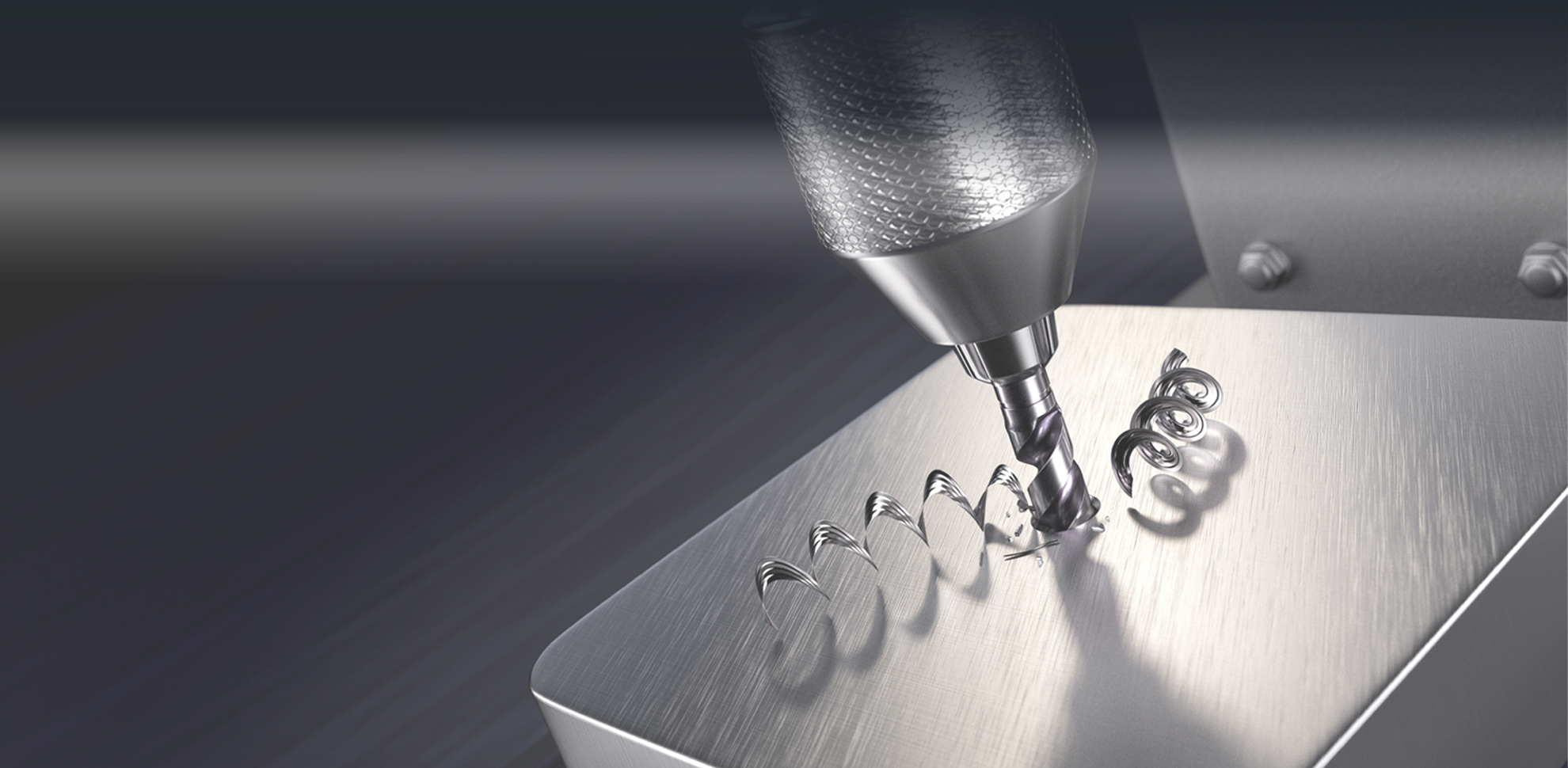

In the process of precision machining, every job is a problem that needs to be paid attention to, especially in the case of precision CNC machining, the details of the machining process are very important. Only in this way can we get good practical results under the working conditions. So what details should be paid attention to in precision CNC machining?

1. Before machining precision CNC parts, check whether a part of the machine is filled with lubricating oil before working, then start and check whether the clutch and braking system are all normal, and run the machine idling for 1-3 minutes. When the machine has common failures Prohibit actual operation.

2, keep the correct posture at work, and have sufficient mental substance to cope with the work. If CNC machining is found to be uncomfortable, you need to leave the post immediately and show it to the leading cadres. During the actual operation, the concept must be centralized, chatting is forbidden, and mutual cooperation is prohibited. Operators must not actually operate under the condition of upset and exhaustion to prevent safety accidents and ensure operational safety.

3, when disassembling and replacing precision parts, first cut off the power, after the high-speed punch motion unit stops running, you can just start to install and adjust the mold. After installation and adjustment, move the water pump flywheel for 2 times to test whether the left and right molds are symmetrical and effective, whether the screws are firm, and whether the edging ring is on an effective position.

When processing precision parts, pay attention to some safety details, otherwise CNC precision processing may lead to product scrap and self-safety problems.

1. Before precision CNC machining, the design drawings of the parts should be clear, and the processing requirements should be reasonable. If there is a problem with the marked size, the processed precision parts may not be used. Affect poor parts processing.

2, precision parts processing operators must maintain the correct posture, have sufficient energy to cope with the work, and focus on each other during operation. Adjust your mentality when you are irritable and tired. So as to avoid accidents.

When operating, pay attention to whether the movement and processing state of the machine tool are normal, and abnormal phenomena are encountered. In the event of noise or alarm, stop the machine immediately for inspection and processing, and then continue to operate and process after the machine tool is faulty.

HTLCNC@163.COM

HTLCNC@163.COM

+086 18682444204

+086 18682444204