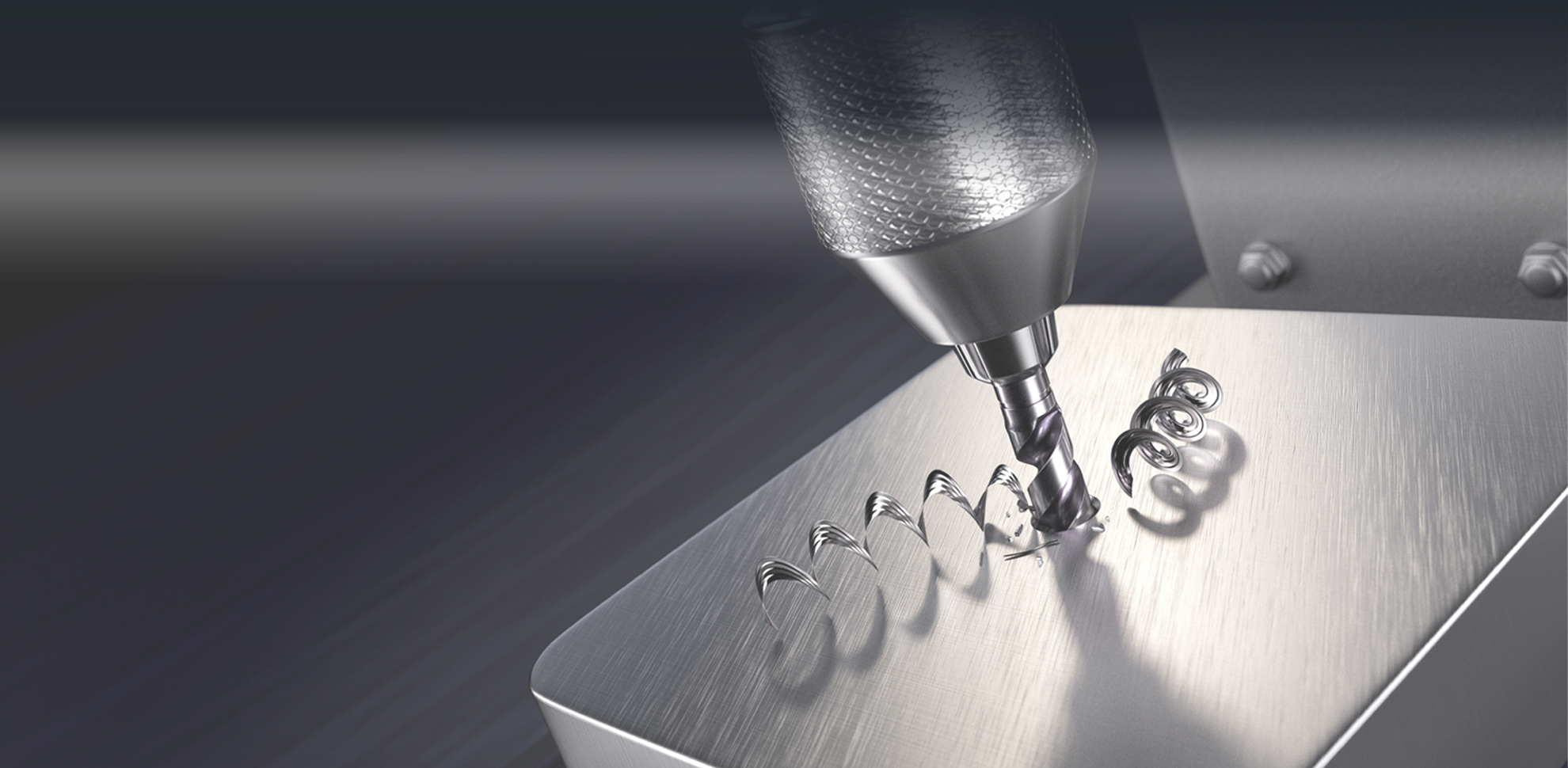

Common technical skills for mechanical processing! In the era of mechanization, many factories have started to use mechanized programs to process some products, which not only improves speed but also greatly improves work efficiency. So, have you summarized any technical skills in the process of using mechanical processing? Many people may not have much time to summarize. Below, Shenzhen Shunchi Precision Machinery will provide a detailed introduction to the commonly used technical skills in mechanical processing:

A process specification is one of the technical documents that specifies the processing technology and operating methods of a part. Under certain production conditions, more reasonable processes and operating methods will be written in the prescribed form in the process documentation. Approved for guidance in production. With technological innovation, experienced Shenzhen Shunchi Precision Machinery has summarized the following common technologies:

Firstly, during the machining process in Shenzhen, remove the jaws of the vice and then machine two M4 threaded holes. The thickness of the jaws of two steel plates 2 is 1.5mm, and the thickness of aluminum rivet riveting is 0.8mm. Brass plate 3 is fixed to the jaw with M4 countersunk head screws 1 to form a durable soft jaw. This can also prevent parts from being squeezed and replaced.

Secondly, using magnets to absorb small parts (cost) in Shenzhen machining is not convenient to absorb. Iron plate 2 can be sucked under magnet 1, which not only attracts many small pieces, but also quickly pulls the small pieces of the iron plate into the collection box. Impression is not enough, but it is very practical.

Furthermore, the belt pulley in Shenzhen mechanical processing often slides between the belt pulley and the axle. On the axle, use? 15? The 18mm drill bit pulls out a series of nests to prevent the adsorption force from sliding, while the boss wastes waste.

In Shenzhen machining, when a hexagonal wrench is short and cannot withstand pressure, a pipe with an inner diameter larger than the wrench can be inserted into the groove and used as a long handle.

In Shenzhen machining, there are many workpieces that are not produced at once, but in workpiece production, this is only a rough model. If the factory becomes a real product, some mechanical equipment needs to be used for processing and processed according to different product requirements. Becoming a valuable product.

In order to ensure processing efficiency and the quality of the products produced, four principles must be followed during the processing process.

1. Benchmark number one: When using mechanical equipment to process products, the origin must be determined to provide positioning reference for subsequent processing. After determining the origin, the origin will be processed.

2. Division of processing stages: When processing products, different degrees of processing are required according to product requirements. The degree of processing needs to be divided. If the accuracy is not high, a simple rough machining stage is required. The product schedule requirements are becoming increasingly strict, and follow the stages of semi precision processing and precision processing.

3. Front and rear holes: For mechanical processing, flat machining and mechanical hole processing are required for workpieces such as brackets. In order to process holes, the accuracy error is small.

4. Sorting and processing: This processing principle roughly involves many polishing and polishing processes, usually after the product has completely completed its structure.

HTLCNC@163.COM

HTLCNC@163.COM

+086 18682444204

+086 18682444204