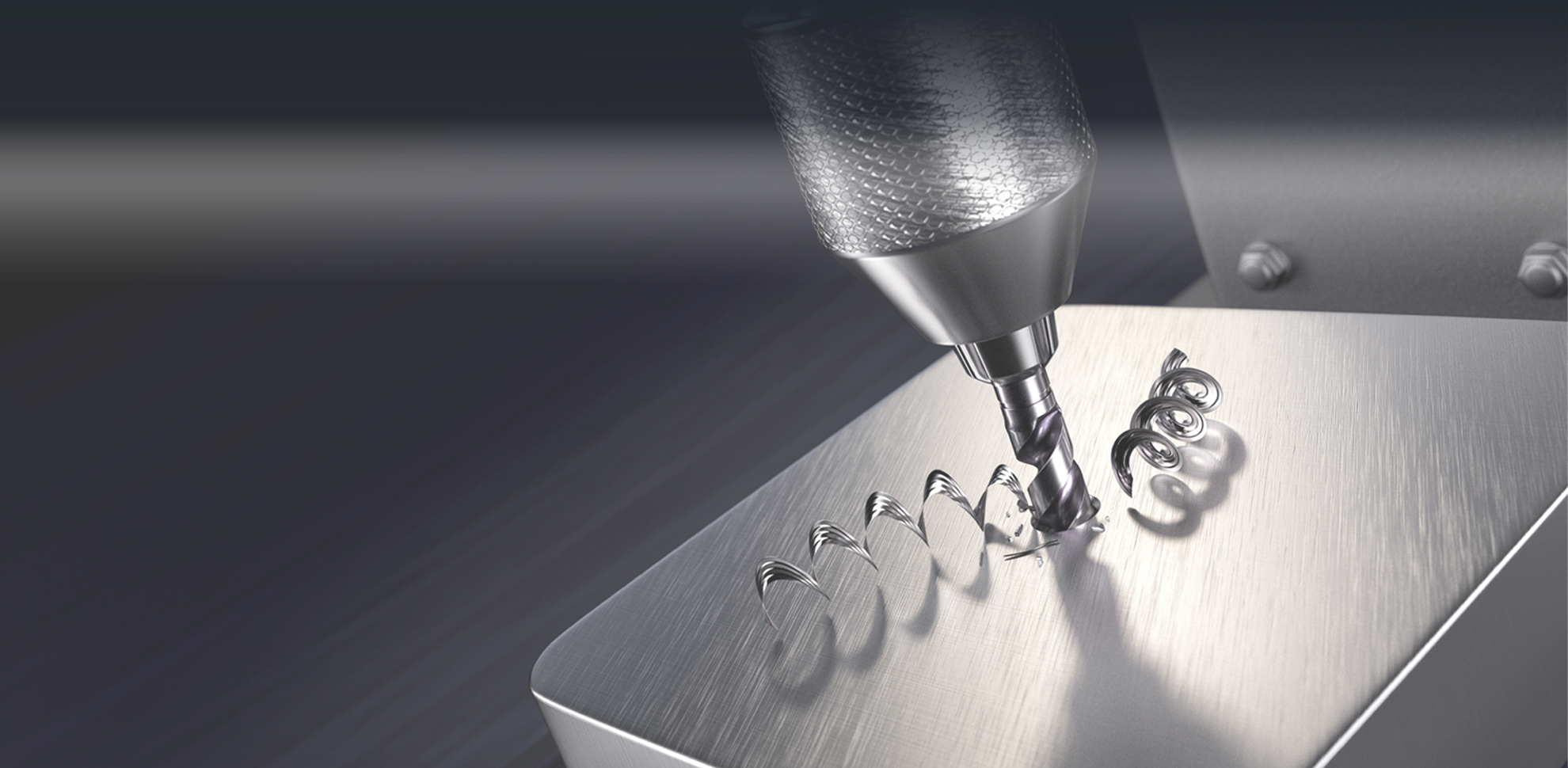

With the passage of time, our various processing methods will also vary, and our precision mechanical processing is also very familiar to everyone. So what are the methods for achieving precision machining?

In terms of hardware, there are many types of mechanical equipment for processing mechanical parts, such as lathes, milling machines, planers, grinders, broaching centers, etc. The inherent processing accuracy of various devices is different, so achieving precision machining depends on how high the accuracy of your parts is. Select the corresponding process route and equipment accordingly;

2. In terms of software, it refers to the skills of operators, involving various equipment operators' skills, including in-depth understanding of the equipment, understanding of processing, and understanding of the parts and materials to be processed. These skills can be gradually accumulated in daily work, and the key to operator skills is practice and understanding of theory.

Mechanical processing refers to the process of changing the external size or performance of a workpiece through a mechanical device. According to different processing methods, it can be divided into cutting and pressure processing.

The machine production process refers to the entire process of manufacturing products using raw materials (or semi-finished products). For machine production, including transportation and storage of raw materials, production preparation, rough manufacturing, parts processing and heat treatment, product assembly and debugging, painting and packaging, etc. The content of the production process is very extensive. Modern enterprises use the principles and methods of system engineering to organize and guide production, viewing the production process as a production system with inputs and outputs.

HTLCNC@163.COM

HTLCNC@163.COM

+086 18682444204

+086 18682444204