What are the 5 common types of machine equipment in CNC machining centers?

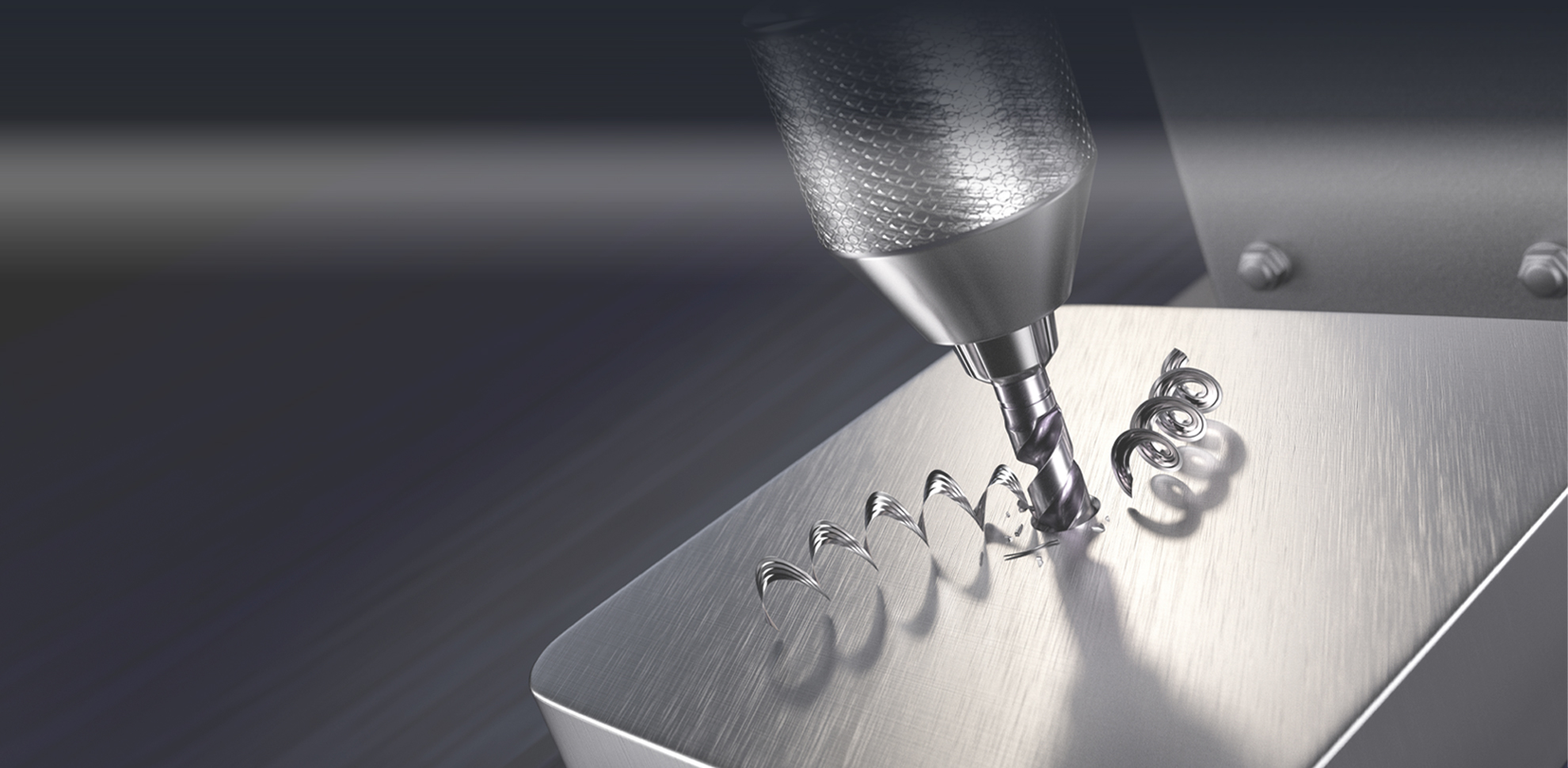

Advanced manufacturing technology is constantly maturing, precision machining machines are widely used, and people have higher requirements for the CNC system of CNC machine tools. People are constantly researching and developing new machining center equipment to meet the needs of enterprise production. The following is a brief introduction to common types of machining centers:

What are the 5 common types of machine equipment in CNC machining centers?

CNC processing

1、 Five axis linkage machining center

The five axis linkage machining center can achieve processes such as milling, boring, drilling, hinge, tapping, etc. There are two key core component technologies for the five axis linkage machining center, one is the dual swing angle universal machining head, and the other is the dual axis rotary table. Large machine tools use dual swing angle universal machining heads, while small machine tools use dual swing axis rotary tables. 2、 Turning and milling composite machining center

This machine tool has a dual spindle, dual tool holder, dual C-axis, and W-axis, consisting of a total of 7 axes, divided into two sets of three linkage full closed-loop control. The parts can be completed in one operation, including turning, indexing eccentric drilling, positioning milling, and other processes.

3、 Turning, milling, and grinding composite machining center

The common CNC turning and milling composite machining center can complete multiple processing of parts for high-precision heavy cutting in one clamping process, suitable for large-scale bearing processing.

4、 Turning and milling gear processing composite center

The second spindle and grinding wheel shaft are installed on the rotating tool holder. The gear cutter and worm gear can be installed on the second spindle to achieve five axis linkage.

5、 Grinding composite machining center

The CNC system of the grinding machining center not only controls the feed of the grinding wheel holder and worktable, but also controls the rotation of the spindle and grinding wheel holder. It can perform cylindrical grinding and automatic indexing of the grinding wheel holder, complete automatic circular grinding of the inner and outer circles and end faces, and is used for various high-precision grinding processes.

HTLCNC@163.COM

HTLCNC@163.COM

+086 18682444204

+086 18682444204