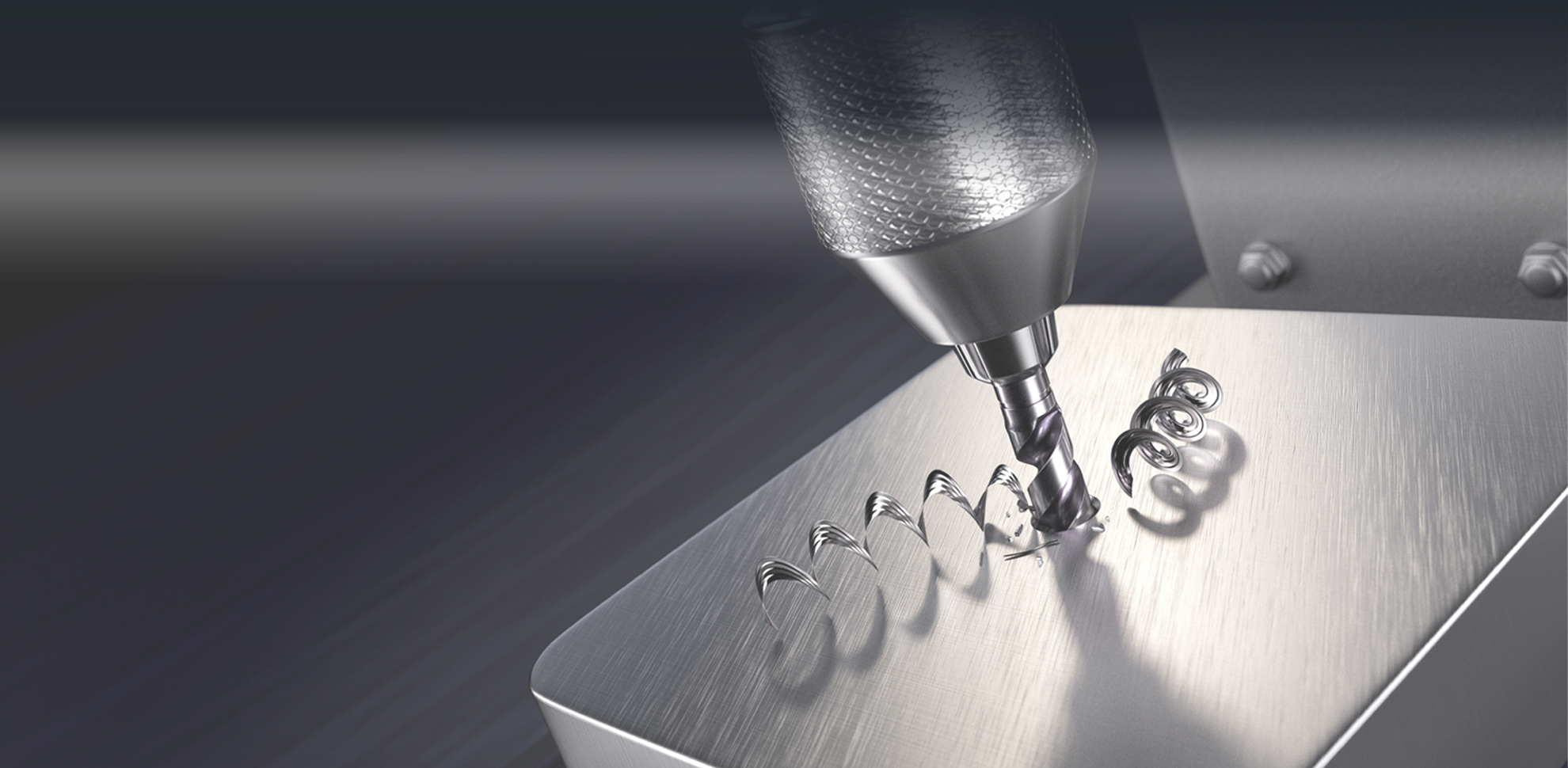

How to solve the inaccuracy and instability of aluminum processing on CNC lathe? Let the Shenzhen Red Wolf Technology cnc processing factory tell you

First of all, under the premise of CNC lathe processing of aluminum materials, the following aspects need to be considered:

1. Force majeure:

1. The stability of the machine tool itself

If it is not a new machine tool or the machine tool has undergone a lot of processing without debugging, there will be dimensional errors caused by the machine tool itself. The following factors cause the error of the machine tool itself:

a. There is looseness between the servo motor and the lead screw.

b. Wear of ball screw bearings or nuts.

c. Insufficient lubrication between screw and nut.

Electrical aspects:

a. Servo motor failure.

b. There is dirt inside the grating ruler.

c. The servo amplifier is malfunctioning.

Regarding system parameters, PMC can be restored, so it is omitted.

2. The workpiece is deformed by cooling after processing

This is basically unavoidable. Try to pay attention to the use of coolant during processing, and pay attention to the deformation of the workpiece after cooling when performing on-site measurement.

The above is about how to solve the inaccurate and unstable processing of aluminum materials on CNC lathes? Do you understand it?

HTLCNC@163.COM

HTLCNC@163.COM

+086 18682444204

+086 18682444204