Hello everyone. I am a staff member of the cnc processing plant of Shenzhen HongTaiLang Technology. As the saying goes, it is good to sharpen knives and not to cut wood by mistake. The effect is that sharpening the knife takes time, but does not delay cutting wood. Metaphor fully prepared in advance can speed up the work. The same applies to our parts processing.

Choosing the right tool can achieve the most ideal finished product effect. In order to provide customers with better service, we have spent a lot of money to hire a number of masters who have been operating machines for more than five years. Come to help us serve our customers, for example. When machining holes, there are precision requirements for some assembly holes, and some industries also have very strict precision requirements for threaded bottom holes. If it is a mass processing, the choice of drill bit is very important in terms of efficiency, cost and quality. For example, to process 6+0.10/0 holes, with 5mm twist drills, the worn holes will be small after a few live drills, and the drills must be reground, which is not only inefficient, but also very costly and difficult to assemble.

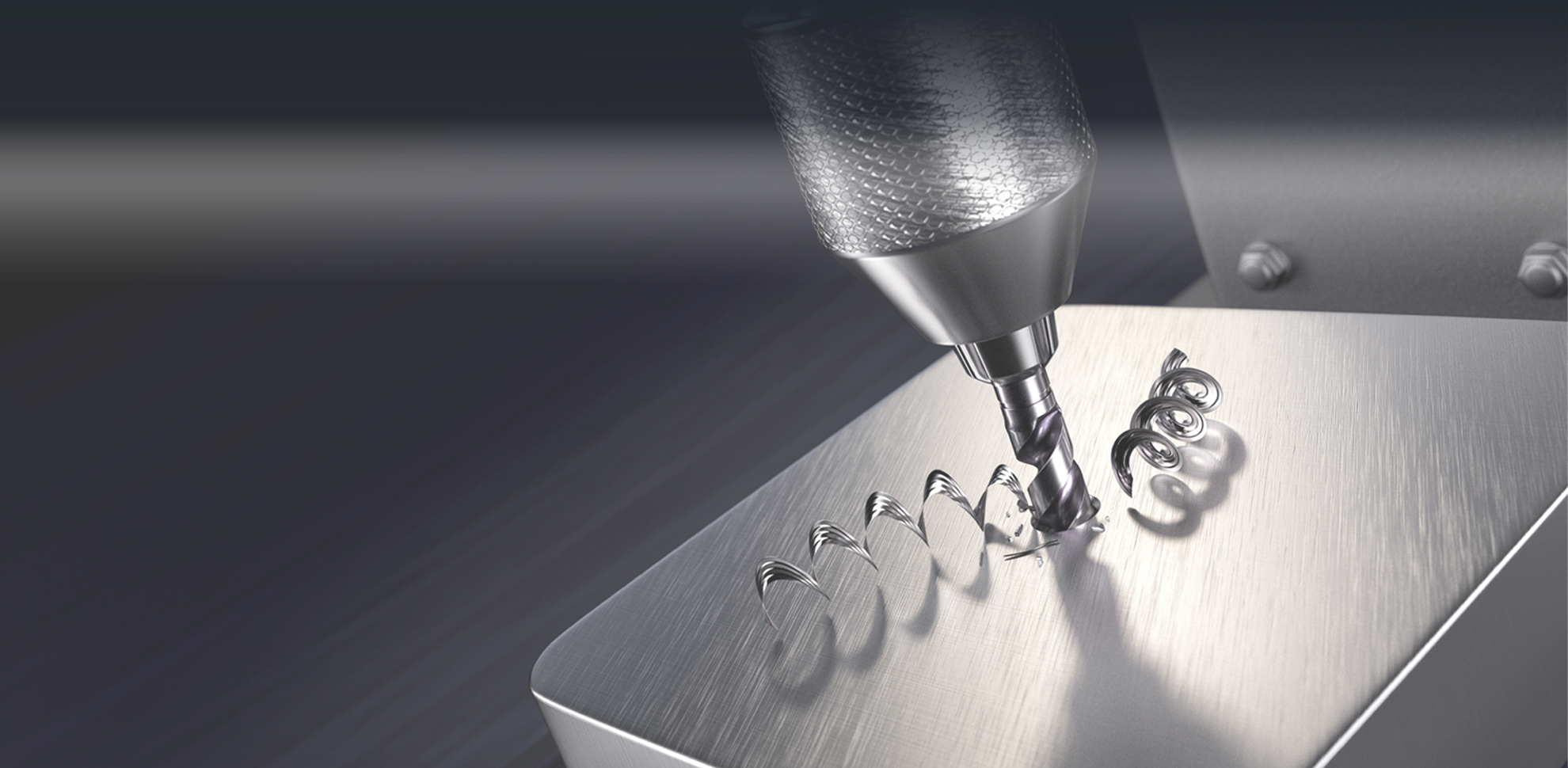

If you use a 5.05 twist drill, it will be different. At least you can process a few hundred pieces and then grind it once, and you can also assemble a lot. But this kind of craft bit is difficult to buy in the market. If you need a large quantity, you can customize it at the tool factory. If the quantity is not large, you can use a larger bit to change the grinding on the cylindrical grinding. The following are some non-standard twist drills used by CNC machines. It can be seen that the spiral angle of the drill is different depending on the processing material. Of course, only a suitable drill bit is not enough to efficiently drill a qualified hole, and an ideal drill clamp is required.

It is necessary to have enough professional knowledge to be able to produce better products to serve a broad customer base. This is the key to the cooperation between many companies and Jianfeng Technology. If you think what I said is right, please don't miss the cooperation with me. Jianfeng Technology is a good choice for parts processing. Thanks for reading

HTLCNC@163.COM

HTLCNC@163.COM

+086 18682444204

+086 18682444204